What Are Diagonal Cutting Pliers And What Are They Used For?

4th Jul 2025

How do you cut wire, over and over, without getting tired?

The answer you’re looking for is diagonal cutting pliers.

But why are these different to other pliers? Why are they so easy to use? And how do you know which ones you need for your job? Find out in this blog, where we’re going to tell you everything you need to know about these quick cutting nippers.

What are Diagonal Cutting Pliers?

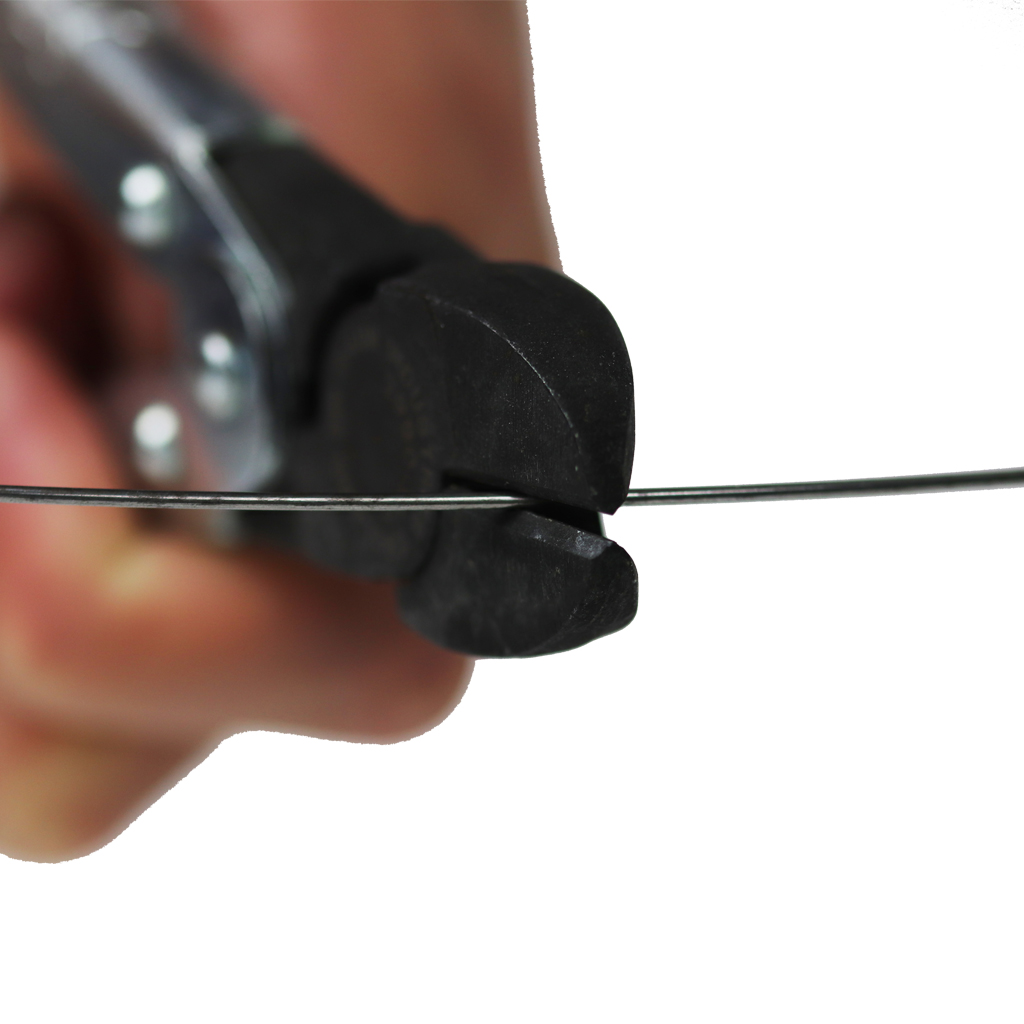

Diagonal cutting pliers are used for cutting wire. They cut wire by indenting and wedging a cable apart (as opposed to shearing like scissors). The name comes from how the cutting edges of the jaws are set at an angle (hence the name "diagonal").

They are also known as side cutters, flush cut pliers, side cutting pliers, wire cutters, diagonal cutting nippers.

Day in, day out, Maun’s diagonal cutting pliers are resilient. Made for repeated cutting of wire, they’ll go easy on your hands. Whatever sector you work in.

Maun’s diagonal cutting pliers aren’t fussy about the type of wire, cable, or lead they cut. Copper, aluminium, steel, soft or hard - they’ll do the trick. They’ll even cut through piano wire, one of the strongest wires out there.

That said, these pliers are specialist tools. With precise cutting edges shaped specifically for cutting wire, they’re designed with the sole purpose of making a clean cut. No compromises.

Browse all cutting pliers here.

How are Side Cutters Different from Normal Pliers?

Side cutters have the following features::

- These pliers can’t grip. They have jaws with cutting edges.

- The jaws have an angled edge. This means they’re designed to cut through wire by applying greater cutting force.

- The jaws and cutting edges are hardened to increase the life of the cutter

- If working on electrical circuits, you should choose insulated side cutters, as they are protected to IEC 60900:2018 standards.

Side cutters are primarily used to cut wire and electronic cables, and are particularly useful at this because the cutting edge creates a clean cut, which improves electronic connections and safety.

How do Maun diagonal cutters differ from standard?

Maun diagonal cutting pliers are a more compact tool than their standard counterpart. This is due to the compound-lever action (with two pivot points), which multiplies the hand force by 18 (140 mm) to 22 (160 mm) times. So, if quick, effortless cutting’s your thing, these are the cutters for you.

Even better, the jaws are induction hardened to HRC 64, a higher level than standard. This results in a heavy-duty tool capable of cutting the hardest wire (e.g. piano wire) without blunting the edges. But they’re just as at home cutting soft wires, like precious metals in jewellery making.

The bottom line is Maun’s diagonal cutting pliers are snappy when you cut wire for a living. They’re more compact, lighter weight and require less effort.

How to use snips

For ease, here’s a step-by-step guide on how to use side cutting pliers (snips):

- Prepare the area you're working in, removing anything that's in the way of you cutting your target piece of material.

- Put on gloves, goggles, and a long sleeve shirt, to avoid the chance of shrapnel hurting you.

- Pull the handles apart to open the jaws.

- For hard wires, place the wire as far down the blades as possible (for the best leverage). For soft, place the wire near the tip.

- Squeeze the handles until you have a solid cut. This may require two hands.

Choosing the right diagonal pliers for the job

Depending on the task at hand (or personal preference), Maun offers two sizes of diagonal cutting pliers. These have different jaw widths and openings.

Option one: 140 mm Diagonal Cutting Pliers from Maun

- 140 mm length

- 10 mm jaw opening

- 8 m jaw width

- Cutting capacity: piano wire 1.6 mm diameter, hard wire 2.0 mm diameter, soft wire 3.0 mm diameter.

More commonly used by dental technicians for orthodontic wire. As well as jewellers, hobbyists, and craft workers.

Alternatively, 2990-140-B, is made for utility meter installers. This is for cutting the multi-stranded wire crimped by Maun’s meter sealing ferrules.

Shop the Maun Diagonal Cutting Plier For Hard Wire 140 mm.

Option two: 160 mm Diagonal Cutting Pliers from Maun

- 160 mm length

- 14 mm jaw opening

- 9 mm jaw width

- Cutting capacity: piano wire 2.0 mm diameter, hard wire 2.5 mm diameter, soft wire 4.0 mm diameter.

More commonly used by engineers and mechanics for hard wire cutting (e.g. welding wire), manufacturers of sprung bed mattresses, piano technicians and electricians.

Shop the Maun Diagonal Cutting Plier For Hard Wire 160 mm.

Both are available in classic finish. With zinc-plated handles with added detailing for better grip. Or with comfort grips fitted.

Watch our Diagonal Cutting Pliers in action:

Related product categories: Small side cutters, Wire cutters, Heavy-duty wire cutters, End cutters, Fence wire cutters, Piano wire cutters, Steel wire cutters, Olive cutters, Cable cutters, Cable tie cutters, and Metal cutting pliers.

How do I buy side cutters online?

If you think Maun’s diagonal cutting pliers are the one for you, shop for a pair online here.

History

Staying Safe When Cutting

These useful cutters can also be dangerous in the wrong hands, so using them safely is important. Make sure to use safety goggles or glasses, wear gloves, and long sleeves to prevent flying debris hurting you. You should also make sure any electrical cables aren't live before making cuts.

Maintenance

If you regularly maintain your side cutters they will last far longer and be more effective in cutting. Before and after use, wipe them clean of any debris, and store them in a cool, dry place to prevent any moisture damage. A small amount of oil in the mechanism can also be beneficial to help the tool run smoothly.

Browse Related Blog Posts:

- Best Wire Cutters

- Best Side Cutters

- What is a straight edge tool?

- What is a wad punch tool?

- How to cut hard wire?

- How to Cut Up Mattress Springs

- What are End Cutting Pliers?

- How to cut laminate flooring?

- How to use pliers?

- Jewellery making tools for beginners

- What are fencing pliers and how are they used?

- What are the best Combination Pliers?

- What is a crimping tool and how are they used?