How to remove a stripped screw

31st Jul 2023

A stripped screw can feel impossible to unscrew, with the indents in the screw head partially or completely worn away.

With nothing to grip, your screwdriver is useless, and more effort often makes the problem worse.

In this post, we discuss the best ways to remove a stripped screw.

The techniques can be categorised into 2 types:

- Increasing friction so that you can unscrew normally.

- Modify the screw head to use a different drill bit/screwdriver.

Method 1: Rubber Band Method

How it works:

- Placing a rubber band in between the screwdriver and the screw head increases friction.

- Use a single band layer for small screws or double it up for larger ones.

Pros:

- Easily accessible

- Non-destructive

- Quick to test.

- Inexpensive, most households will have a rubber band.

Cons:

- Likely not to work for severely stripped screws.

- Requires considerable force to work.

- Rubber band fragments may remain after the attempt.

- Hard to work on recessed screws.

Method 2: Flathead Screwdriver

How it works:

- Using a flathead screwdriver of a similar size to the width of the screw, lodge it into the Phillips screw head and unscrew gently.

- After you’ve exposed the top, use pliers to unscrew the remaining section.

Pros:

- Uses tools most people will own.

- Gives good feedback, so you can gauge the resistance and whether it’s working.

Cons:

- Can further damage the screw, making it harder to remove.

- Less likely to work on deep or small screws.

- Risk of slipping and causing injury.

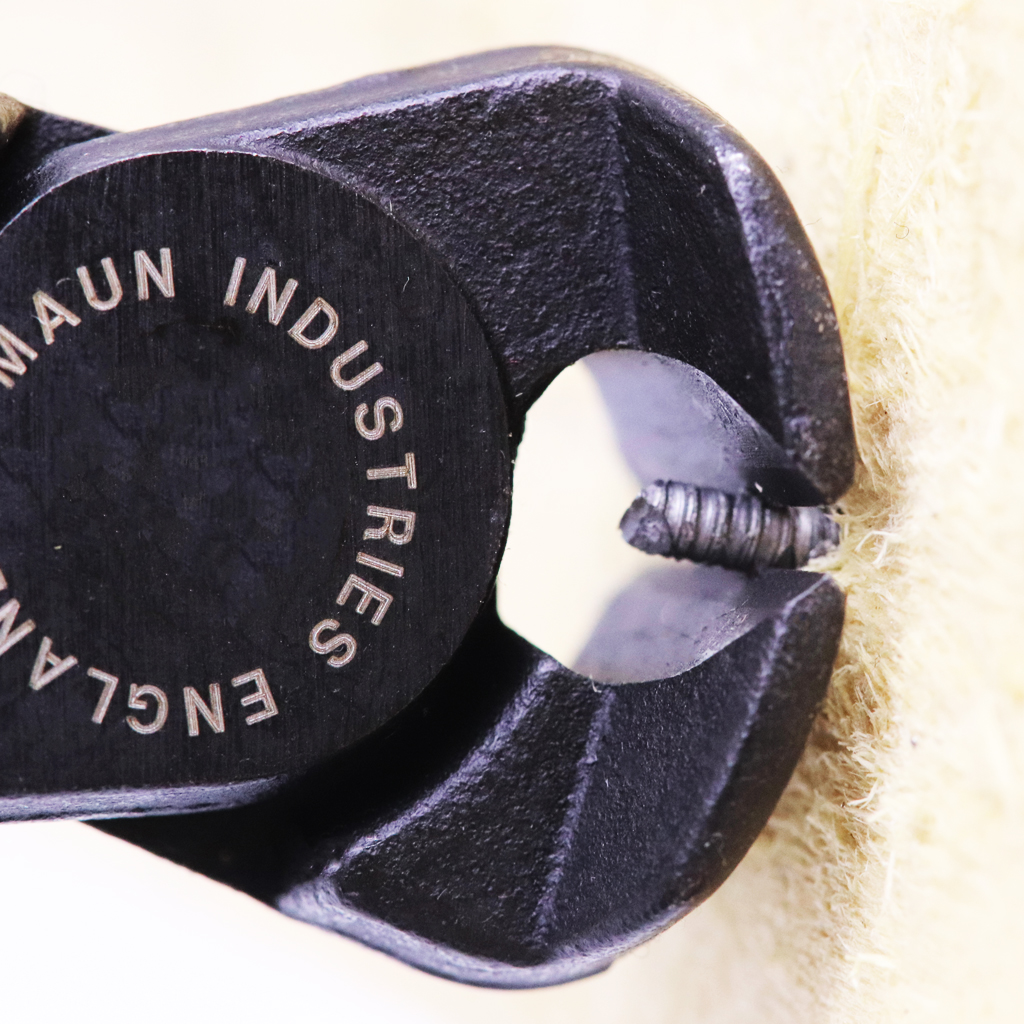

Method 3: End Cutting Pliers

How it works:

- Grip the outer edge of the screw, and turn counter-clockwise to remove it.

- The flat-end jaws help you get underneath even slightly recessed screws.

- We recommend the Maun End Cutting Pliers for this.

Pros:

- Works on screws of all sizes.

- Provides excellent leverage, making it easy to turn stubborn screws.

- The thin jaws allow purchase on flush and slightly recessed screws.

Cons:

- Can damage the material surrounding the screw if not used properly.

- Likely not to work well on deeply recessed screws.

Method 4: Parallel Pliers

How it works:

- Parallel jaw pliers offer a firm grip on the screw head.

- Apply firm pressure on the screw head and unscrew the screw.

- For the best results, choose a set with serrated jaws, like these Flat Nose Parallel Pliers.

Pros:

- Parallel jaws offer an effective grip.

- Can be used on multiple-sized screws.

- Apply far more leverage than a normal set of pliers.

Cons:

- Hard to use on deeply recessed screws.

Method 5: Hammer and Chisel

How it works:

- Using a hammer and chisel, to create a new slot in the top of the screw.

- This can then be unscrewed with a standard flathead screwdriver.

Pros:

- Creates a large groove for simple turning with a screwdriver.

- Uses commonly owned tools.

Cons:

- Can damage surrounding material.

- Potential danger of the chisel slipping on the screw head.

Method 6: Screw Extraction Kits

How it works:

- Custom drill bits that spin in the opposite direction of an ordinary screw.

- First drill out a pilot hole in the bottom of your screw head (some packs come with a specific drill bit end to do this).

- Then swap to the extraction bit, apply pressure, and unscrew slowly.

- The bit then digs into the metal of the screw, helping you to unscrew it.

Pros:

- An effective solution as it’s designed for the job.

- Usually comes with multiple sizes to handle all screw types.

Cons:

- Requires a dedicated kit, as opposed to commonly owned tools.

- Often creates metal fragments that create a mess.

- Requires a level of skill to perform safely.

Tips to Prevent Stripped Screws in the Future

If you want to avoid this next time, here’s what you can do to prevent stripped screws in the future:

- Use the right screwdriver or bit: when you use the wrong size of screwdriver or drill bit, there's not as much friction, increasing the chance of it slipping and stripping the screw head.

- Proper alignment: always try to align the drill bit up properly with the screw, as drilling on an angle reduces friction and increases the chance of damage.

- Consistent pressure: maintain consistent pressure when screwing, as inconsistent pressure is likely to result in less friction which will cause the bit to slip in the screw head.

- Pilot holes: pre-drilling pilot holes mean you’ll require less effort to screw your screws in, and so less chance of slipping.

- Avoid over-tightening: when using a power drill, it’s easy to overtighten your screws, which can result in stripping them initially, or making them impossible to remove without stripping them if you need to disassemble.

Conclusion

Now you should have plenty of techniques to try and remove a stripped screw in your next project.

Need a new set of pliers? Choose Maun

Scroll back up to re-read any confusing steps, browse our related posts below, or contact us with any questions: