How To Choose Wire For Jewellery Making

19th Feb 2024

Jewellery making is a lot easier when you choose the right wire for the job.

The key considerations when choosing wire are the wire material, thickness (gauge), hardness, and shape.

In this post, we’ll discuss how to choose the best type of wire for your next project.

Choosing Wire Materials

Different wire materials have different appearances, malleability, and durability, so it’s crucial to get this choice right for your next project. Here’s a quick breakdown of each:

- Gold wire: Gold provides a luxurious appearance and doesn’t tarnish easily. However, it’s quite expensive and is softer (making it more prone to bending and wear). It’s best for high-end jewellery such as necklaces and earrings, and likely more appropriate for experienced jewellers.

- Silver wire: Silver offers a classic and versatile appearance, and is more affordable than gold. It’s also easy to manipulate. However it will tarnish over time, and the softness can deform if not handled with care. It’s great for beginners and experts alike.

- Copper wire: Copper is great for beginners, as it’s low cost and easy to shape. However it’s not as durable as precious metals, and it can turn the skin green.

- Aluminium wire: Aluminium is cheap, lightweight, and resistant to tarnishing. However, it is less durable and is likely best for hobbyists or crafters creating fun, costume jewellery.

- Nickel wire: Nickel is very durable, and offers a lower-cost silver alternative. However, it can cause an allergic reaction in some. It’s best as a silver alternative when you’re practising more complicated techniques.

*Did you know? One of the main issues with handling precious metals during jewellery making is crushing or marking it, which can get expensive and ruin your jewellery piece.

That’s why Maun developed the V Notch Wire Holding Pliers with the Birmingham School of Jewellery, allowing you to grip precious metal wire firmly without damaging it.

Choosing Wire Thickness (Gauge)

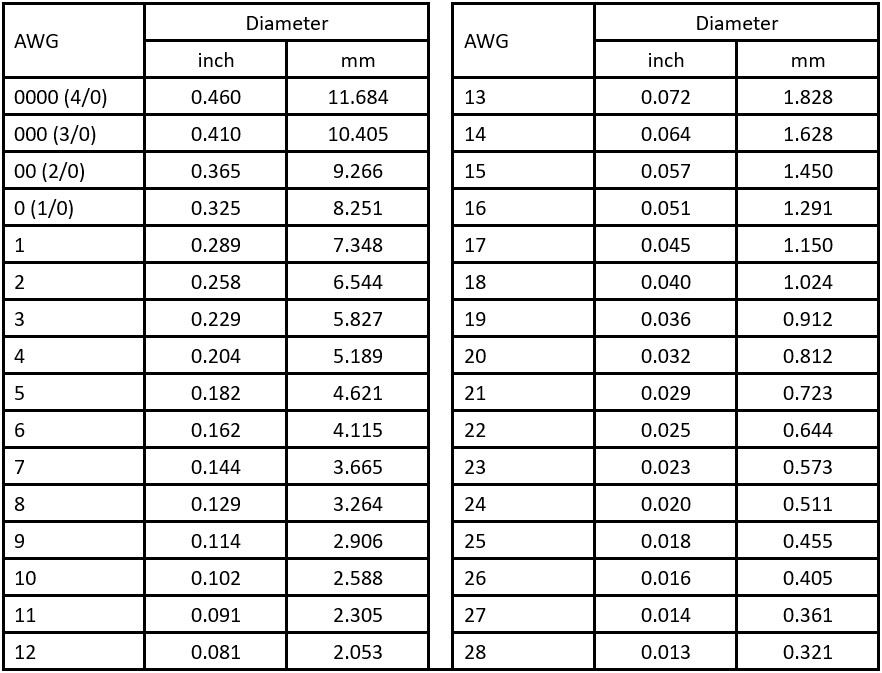

Wire thickness is normally measured across the diameter in millimetres, or defined using the American Wire Gauge scale (AWG). Unusually, the AWG value is inversely proportional to the measured thickness of a wire (the higher the value, the thinner the wire).

Wire Thickness and AWG Conversion Table

Thicker wires (with lower gauge numbers) are more robust and will better hold their shape when finished, making them ideal for structural components within jewellery pieces, or for pieces that will get a lot of use.

Thinner wires (higher gauge numbers) are more easily bent and allow for more intricate designs, making them ideal for highly decorative pieces.

*Did you know? The cutting edge of most low-quality cutting tools may blunt or become damaged when cutting through hard wire, which may slow you down, marr or otherwise mark your materials, and potentially cost you money.

That’s why we recommend you upgrade to this Diagonal Cutting Plier For Hard Wire, which is specifically designed to handle the harder or larger diameter jewellery wire with ease, thanks to the high-leverage design and compound-lever action that multiplies hand force by 18.

Jewellery Wire Hardness

Jewellery wire hardness determines how easily wire can be manipulated. Softer wire is best for beginners or when completing a more intricate design, whereas harder wire is best for jewellery that will be frequently worn or needs to be more robust.

Hardness for jewellery wire is categorised into these three types:

- Soft Wire: Ideal for more intricate designs, where you need to be very precise. It’s also great for beginners, as it’s easier to work with. However, it has greater limits when considering its ability to hold its shape under stress or weight.

- Half-hard Wire: Ideal for general components like ear wires, clasps, and jump rings. The perfect balance between flexibility and strength, making it versatile for many projects.

- Hard Wire: Used for structural elements in jewellery like bracelet frames and rigid components. Preferred by advanced users with professional tools, and for pieces that need considerable support.

Jewellery wire hardness should not be confused with ISO standards for wire hardness. The categorisation for jewellery wire broadly features at, or below, the ISO specification for “Soft Wire.”

*Did you know? Cutting through soft wire with the incorrect tool can create a pinch that leaves you with a lot of finishing work to do. That’s why Maun developed the Smooth Jaws Super Flush Cut Side Cutter Parallel Plier 125 mm, allowing you to manipulate precious metal wire without marring it, and cut it cleanly with little to no pinch.

Wire Shape

Choosing different wire shapes can add a new dimension to your jewellery design. The typical shapes you will encounter are:

- Round Wire: Round wire is versatile and useful for both beginners and professionals. It can be used to create standard loops, jump rings, ear wires, and spirals.

- Square Wire: Square wire is ideal for structural designs where you need a flat surface for stacking or aligning different elements. It also offers a more contemporary look, and can create interesting textures.

- Half-round Wire: The main use of half-round is for rings and wire wrapping, around other components in your piece. Being flat on one side and round on the other, allows it to conform well around round wires.

- Twisted Wire: Twisted wire is used for decorative braiding and ornamental accents. It’s created by twisting two or more strands of wire together.

- Bezel Wire: Bezel wire is used to create bezels (frames) for setting stones, and tends to be softer and more malleable.

Best Wire for Each Type of Jewellery

1. Necklaces

- Chain Necklaces: Thinner, more flexible wire (22-28 gauge) is suitable for delicate chain necklaces. Choose dead soft or half-hard round wire, in precious metals for a high-end look (or copper/brass for practice).

- Statement Necklaces: Thicker half-hard wire (16-20 gauge) for structure and durability.

- Beaded Necklaces: Flexible, thin dead soft wire (24-28 gauge) that can pass through beads easily.

- Chokers: Memory wire or thicker gauge half-hard wire (18-20) for maintaining shape.

2. Bracelets

- Bangles: Stiffer, thicker wire (14-18 gauge) to maintain shape. Choose half-hard or full-hard.

- Beaded Bracelets: Flexible, thin dead soft wire (24-28 gauge) for stringing beads.

- Cuff Bracelets: Half-hard or full-hard wire (16-20 gauge) for structural integrity.

- Charm Bracelets: Medium gauge half-hard wire (20-22) for attaching charms and providing flexibility.

3. Earrings

- Dangle Earrings: Flexible, thinner wire (22-26 gauge) for hanging elements. Choose dead soft or half-hard.

- Stud Earrings: Stiffer half-hard wire (18-20 gauge) for the post; dead soft wire for decorative elements.

- Hoop Earrings: Medium to thick gauge half-hard wire (18-20) for maintaining hoop shape.

- Wire Wrapped Earrings: Half-hard wire (20-24 gauge) for wrapping.

4. Rings

- Band Rings: Thicker, stiffer half-hard wire (16-18 gauge) to maintain shape.

- Wire Wrapped Rings: Flexible yet sturdy half-hard wire (20-22 gauge) for wrapping and detailing.

- Beaded Rings: Thin, flexible dead soft wire (24-26 gauge) for adding small beads.

5. Brooches and Pins

- Brooches: Thicker, stiffer half-hard wire (16-18 gauge) for the frame and structure.

- Decorative Pins: Medium gauge half-hard wire (20-22) for both structure and decorative elements.

6. Hair Accessories

- Hairpins and Clips: Medium to thick half-hard wire (18-20 gauge) for strength and durability.

- Headbands: Flexible half-hard wire (20-22 gauge) that can be moulded to shape.

7. Anklets

- Anklets: Similar to bracelets, but considering the additional movement and potential for wear, flexible, durable half-hard wire (20-24 gauge) is often used.

8. Body Jewellery

- Nose Rings, Belly Rings: Hypoallergenic, non-reactive metals; thickness varies based on design (20-24 gauge commonly). Choose half-hard wire.

Conclusion

Hopefully this guide will help you make a more informed decision about which type of wire to use for your next jewellery project.

If you have any feedback or improvements you’d recommend for this post, we’d love to hear from you.

This post was brought to you by Maun, experts in tools since 1944.

Scroll back up to re-read any key points, browse our related pages below, or contact us with any questions: