What Are Mini Pliers And How Are They Used?

14th Apr 2025

How small are mini pliers, actually?

And when should you opt for them instead of their full-sized counterparts?

In this brief guide, we'll explore the size, applications, and scenarios where mini pliers are most suitable tool for the job.

What are Mini Pliers?

Mini or micro pliers are simply smaller versions of pliers designed for when you need more precision when gripping, bending, or cutting.

They tend to have smaller jaws and shorter handles and weigh less than normal pliers.

Their compact size allows users to work in tight spaces where regular pliers are too large.

Why Use Mini Pliers Instead of Normal Pliers?

The main benefit of using mini pliers over normal pliers is being able to make precision movements in tight spaces without damaging delicate materials.

They allow better control when working on electronics, jewellery, or small mechanical parts.

Their compact size also reduces hand fatigue and improves accuracy during detailed tasks.

Full-size pliers exert too much leverage and hide your work beneath bulky jaws.

Important Features

If you’re looking to buy mini pliers, keep an eye out for these important features:

- Compact Size: They should be smaller than normal pliers, which makes them better for precision tasks and in tight spots.

- Precision Jaws: Whether flat, round, or needle-nosed, the jaws should be precision-machined to fit together accurately, which gives a better grip (particularly important for smaller components).

- Lightweight Construction: They should be lighter than normal pliers, helping to reduce your hand fatigue when using them for extended periods.

- Parallel-Action Jaws: This ensures an even, secure hold along the full length of the jaw (due to the increased surface area of contact) meaning you need less effort and so can work more precisely.

- Compound-Lever Cutting Action: This provides exceptional cutting power without much effort, meaning you can work faster and for longer without sacrificing cutting strength.

- Open-Throat Design: If you work with longer lengths of wire, an open throat design lets you manipulate the wire over the full length, by feeding it through the centre of the pliers.

- Precision Hardening: Jaws and cutting edges are hardened to HRC 57, providing superior longevity, performance, and resistance to wear and rust.

Looking to buy mini pliers? Browse the Maun range here.

Types of Mini Pliers & Their Uses

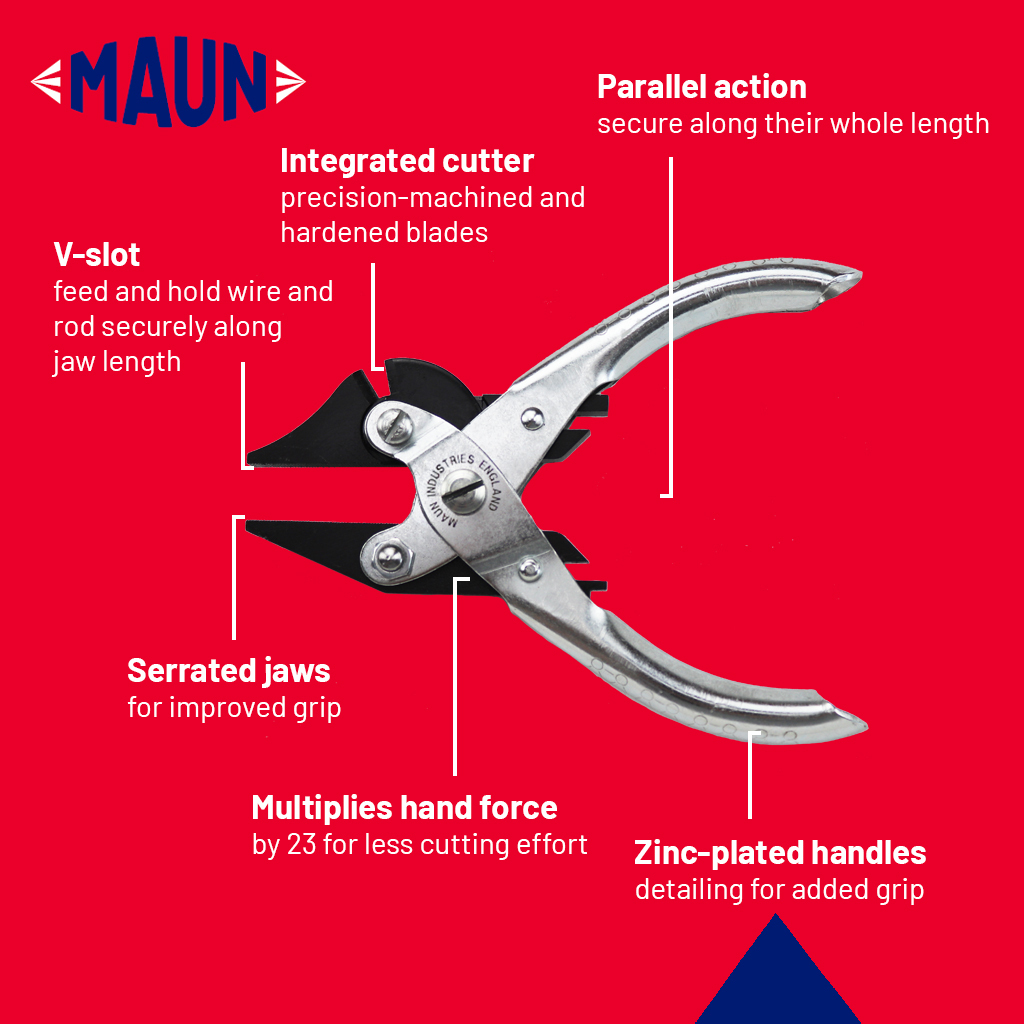

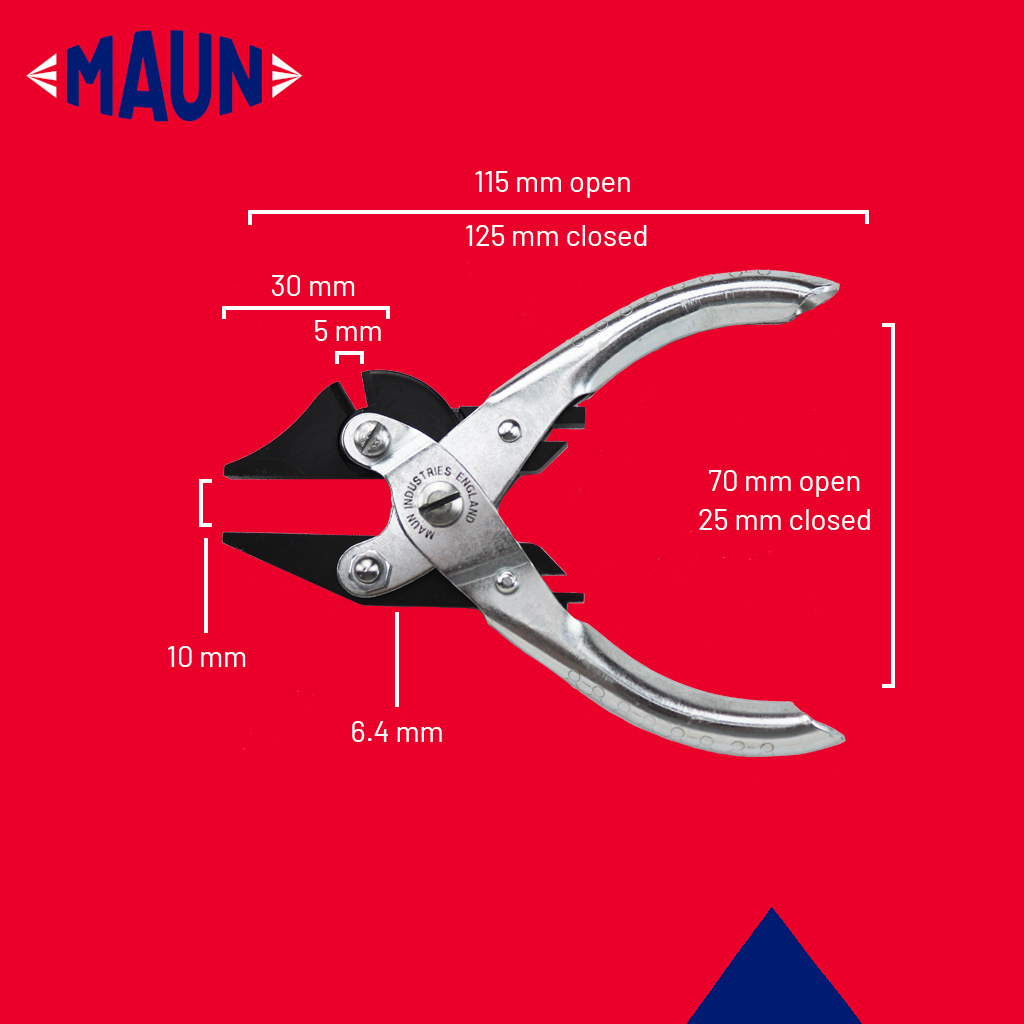

Mini Flat Nose Side Cutter Parallel Pliers

The perfect mini combination plier.

- Compact combination plier with both parallel-action jaws and a compound-lever-action cutter.

- Offers up to 23x cutting force for easier, cleaner cuts.

- PVC grips for comfortable, reduced-strain usage.

- Precision-machined jaws, hardened for long life and durability.

Used for:

- Cutting and gripping wire, cable, or rods in electronics and precision work.

- Holding small fasteners securely with parallel jaws.

- Ideal for light assembly, jewellery making, or compact machinery repairs.

Browse them here.

Mini Flat Nose Parallel Pliers

Your everyday mini plier.

- Compact, parallel-action plier with serrated flat jaws.

- Provides a vice-like grip along the entire jaw length.

- PVC grips and return spring for added comfort.

Used for:

- Gripping, straightening, and manipulating wires or small components.

- Holding fasteners firmly without slipping.

- Common in electronics assembly and repair.

Browse them here.

Mini Smooth Jaw Flat Nose Parallel Pliers

Perfect for working with delicate materials.

- Similar to the flat nose version but with smooth, non-marring jaws.

- Protects delicate finishes, soft metals, and sensitive parts.

- Parallel action provides even grip pressure.

Used for:

- Perfect for jewellery, watch repair, and fine craftwork.

- Handling soft metals, polished parts, or components where the surface finish matters.

- Used in prototyping, model-making, and delicate assembly tasks.

Browse them here.

Mini Snipe Nose Parallel Pliers

Ideal for working in tight spaces.

- Tapered, fine-point serrated jaws for reaching into tighter spaces.

- Maintains a secure grip thanks to parallel-action design.

- Ergonomic PVC handles for reduced hand fatigue.

Used for:

- Precise bending and positioning of wires or components in tight assemblies.

- Ideal for electronics, model-making, and intricate mechanical work.

- Accessing awkward, narrow spaces.

Browse them here.

Also available in a smooth jaw variant for working with delicate materials (such as in jewellery making).

Mini Fine Nose Round Jaw Parallel Pliers

Perfect for creating loops and precision curves.

- Smooth conical jaws with fine round tips.

- Excellent for creating tight loops and bends without damaging material.

- Parallel action for consistent grip strength.

Used for:

- Forming loops in wire or chain links.

- Jewellery making, chainmail, or intricate wirework.

- Perfect for precision shaping, bending, and forming components in electronics or crafting.

Browse them here.

Mini Soft Plastic Jaw Flat Nose Parallel Plier

Even softer jaws for very delicate work and high-finish materials.

- Flat nose plier with soft, replaceable plastic jaws.

- Prevents marking or scratching of high-gloss and delicate components.

- Parallel jaws offer stable and uniform grip pressure.

Used for:

- Handling chrome-finished parts, glass, or delicate surfaces.

- Working on decorative fittings, jewellery, or soft metals.

- Ideal for restorers, repairers, jewellery-makers, and specialist craftspeople.

Browse them here.

Alternatives to Mini Pliers

The main reasons to not use mini pliers are:

- More leverage: If you need a very strong grip, larger pliers will provide you with more leverage for that purpose.

- Reaching further into tight spaces: If your mini pliers don’t reach the component, then you’ll need long nose pliers instead.

Final Summary

That’s everything you need to know about mini pliers.

If you have any feedback or improvements you’d recommend for this post, we’d love to hear from you.

This post was brought to you by Maun, experts in tools since 1944.

Scroll back up to re-read any key points, browse our related pages below, or contact us with any questions: