What are Long Nose Pliers & How Are They Used?

24th Sep 2025

Have you ever struggled to grip an object just out of reach or manipulate materials in a confined space?

Long nose pliers are the solution.

Engineered for precision, they reach where other tools fall short, provide a firm grip where fingers fail, and handle delicate tasks with exceptional control.

Learn all about them below.

What are Long Nose Pliers?

Long nose pliers have long, tapered jaws designed for gripping in tight, hard to reach spaces.

They have tapered jaws that reduce the bulk associated with regular pliers, offering more precision, and helps to keep your workpiece visible.

They are slightly different to needle-nose pliers, which tend to be much thinner and user for fine detail work (such as in jewellery) but sacrifice strength of grip and durability.

Chain nose pliers are similar in design but normally feature a smooth jaw as opposed to a serrated jaw. These are commonly used in jewellery making, model making and electronics assembly and maintenance.

The long nose plier differs from the snipe nose plier, as the snipe nose generally taper down to a finer point at the tip.

It is not uncommon for the four terms, Long, needle, snipe and chain, to be used universally alongside “nose” to describe any plier that has a rounded outer nose, with a tapered, long jaw.

Where are They Commonly Used?

Here are the common uses for long nose pliers:

- Electrical work – Gripping, twisting, and positioning wires without damaging them in hard to reach areas.

- Industrial maintenance and repair – Useful for gripping springs, fixings and other items in tight corners, bending metal brackets, repairs inside machines and panels, and preparing wire and cable for installation.

- Model building & jewellery-making – Bending and shaping metal without slipping, although smooth-jaw needle-nose pliers would be more appropriate for soft metals.

- Automotive repairs – Ideal for extracting fuses, holding nuts in place, or working inside engine compartments where hands can’t reach.

- Fishing & Outdoor Gear Maintenance – Helpful for extracting hooks, repairing reels, or adjusting small mechanisms on equipment. You can browse the range from Maun here.

Main Benefits of Long Nose vs Regular Pliers

So why choose long nose pliers over standard ones?

Simple: they reach, grip, and manoeuvre where other tools fail.

- Precision Control – Their elongated shape allows for gripping tiny objects without crushing them, perfect for electronics, delicate hardware, or detailed craftwork.

- Accessing Tight Spaces – Whether reaching deep into a cabinet to retrieve a washer or navigating an engine’s wiring harness, their narrow jaws fit where other tools cannot.

- Bending & Shaping Materials – Ideal for creating clean, controlled bends in metal wire or holding a component firmly while shaping it to fit a repair.

- Holding Small Objects Securely – When fingers are too large or slippery, long nose pliers provide a steady grip, even on fine or awkwardly shaped objects.

Consider an electrician trying to twist two wires inside a crowded switchboard. With short, stubby pliers, achieving a firm hold is impossible, and could damage surrounding wires. And your fingers have no change of reaching, particularly if you’re wearing gloves. Whereas the long, tapered jaw of long nose pliers offers the accuracy and gripping required to do a professional job - all without disturbing surrounding components.

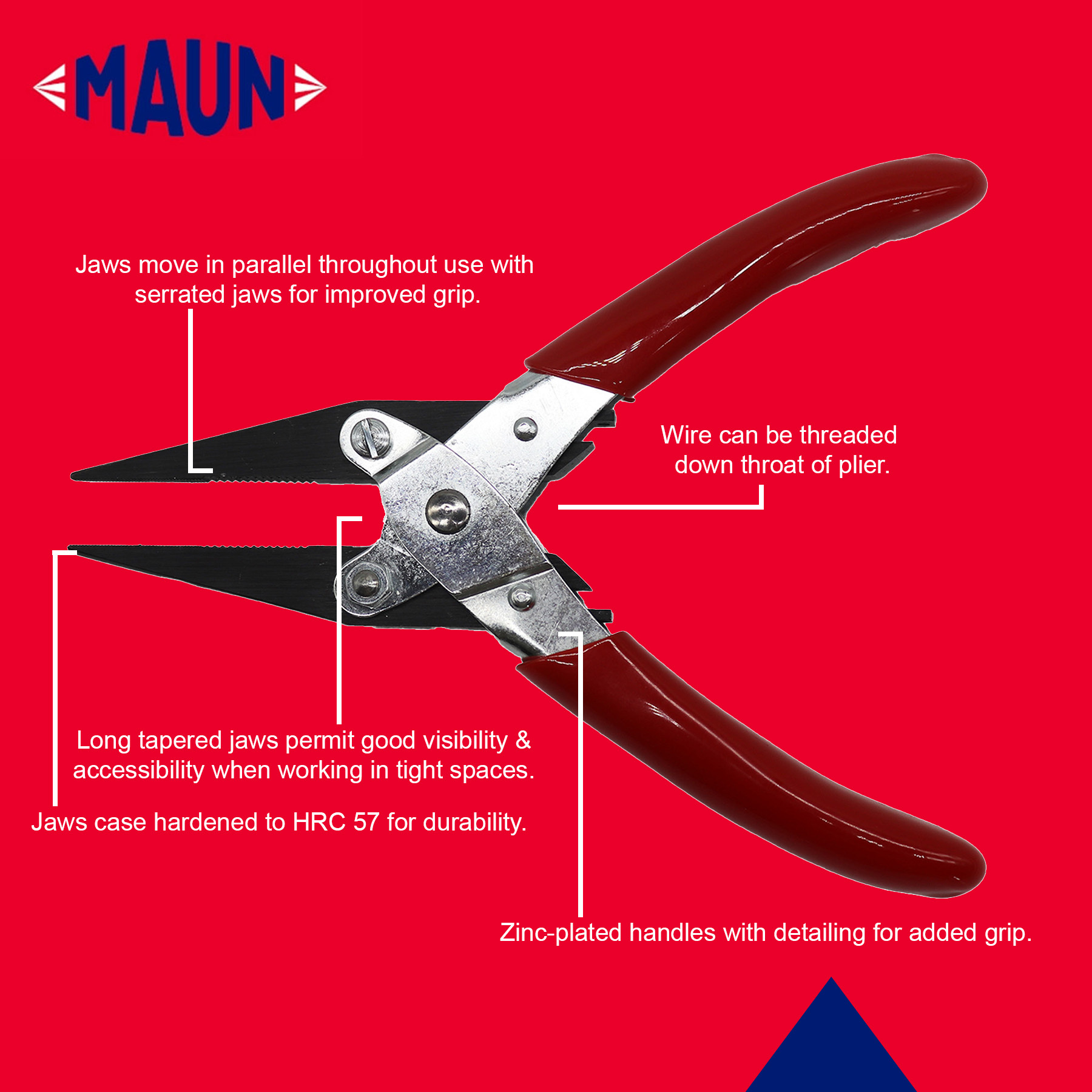

Important Note: Parallel-Jaws vs Scissor-Action Long Nose Pliers

Traditional long nose pliers suffer from a few key issues which make your job more difficult:

- Grip consistency: the pinching grip of the scissor-action gives you a small contact area on the piece you’re working with, meaning you have to apply a lot of pressure to achieve the right grip. This can damage certain wires/cables, but also leaves you prone to dangerous slips.

- Tip span: the tips of the scissor-action pliers splay outwards from the object you grip, meaning they take up more space than the object itself, which can be impractical in tight spaces.

The solution? Parallel-Jaw Long Nose Pliers

- Stronger, More Even Grip: Parallel jaws provide full contact along their length, making them better for gripping small, delicate, or cylindrical objects without slipping or damage.

- Improved Precision & Accessibility: A smaller tip span and consistent grip allow for better control in tight spaces, making them ideal for electronics, jewellery, and intricate work.

- Better Handling of Wire, Cables & Fasteners: The open throat design enables wire feeding and pulling, while larger contact areas improve grip on nuts, bolts, and round objects.

- Reduced Hand Strain & Increased Efficiency: Secure, even clamping reduces jaw slippage and the need for constant readjustment, making them easier to use for extended periods.

Browse long nose parallel pliers here.

Types of Long Nose Pliers

While each type have the long jaws, they each have unique characteristics which we’ll detail below:

- Standard Long Nose Pliers – The all-purpose choice for gripping, twisting, and bending wire.

- Long Nose Parallel Pliers – The jaws remain perfectly parallel throughout the gripping range of motion, giving you a more accurate, uniform grip on objects vs the traditional scissor-action. Check out the Long Nose Parallel Plier Comfort Grips 200 mm.

- Long Nose Combination Pliers – All the benefits of the long nose pliers with a built-in cutting edge, to avoid you having to switch between tools which saves you time.

- Long Nose Side Cutter Parallel Pliers – The jaws remain perfectly parallel throughout the gripping range of motion, and the plier has a cuter jaw on the outer edge of the plier with a compound-lever action. Check out the Long Nose Side Cutter Parallel Plier Return Spring 160 mm.

If working with live circuits, always use certified insulated pliers—standard rubber-coated handles do not guarantee electrical protection.

Final Summary

That’s everything you need to know about long nose pliers.

If you have any feedback or improvements you’d recommend for this post, we’d love to hear from you. This post was brought to you by Maun, experts in tools since 1944.

Scroll back up to re-read any key points, browse our related pages below, or contact us with any questions: