What Are Insulated Pliers and How Are They Used?

28th Jul 2025

When working with electricity, safety has to come first.

In this article, we’ll break down exactly what insulated pliers are, how they’re made, and when you should be using them.

Whether you're a professional electrician or tackling DIY electrical work, knowing the difference could keep you safe - and maybe even save your life.

What Are Insulated Pliers?

Insulated pliers are specialist hand tools engineered to protect users against electric shock when working on live or potentially live electrical systems.

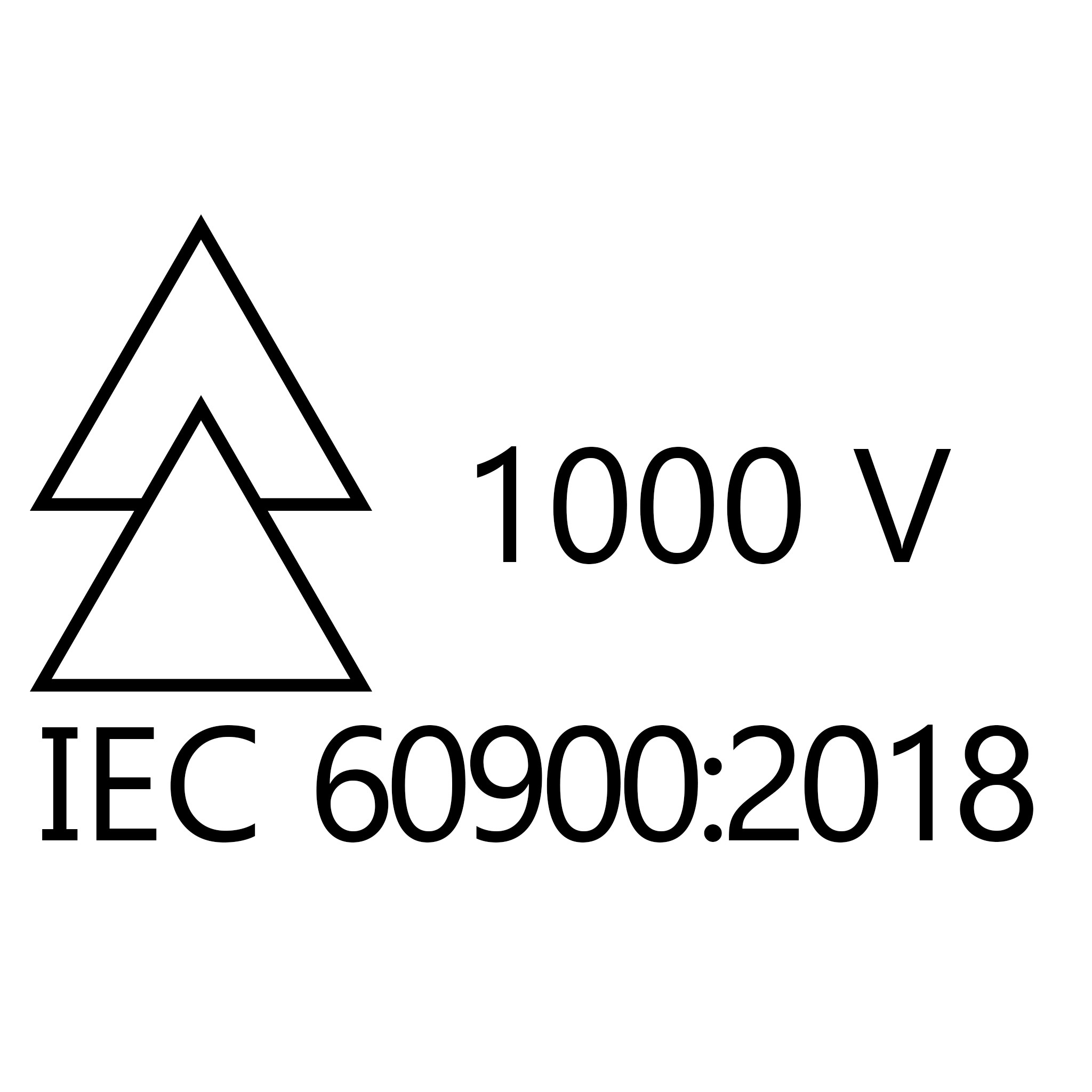

The tool handles are coated with a non-conductive material, that must protect the user from up to 1000V AC/1500V DC, and comply with IEC 60900:2018 standards.

The key benefit of using insulated pliers is protection from electrical shocks. Even in situations where circuits should be off, faults like backfed power or incorrect labelling still pose a risk, and so insulated pliers act as a safety net in these situations.

What does VDE mean? VDE is simply an independent company that tests tools to the IEC 60900:2018 standards. It isn’t an official requirement for the tool to be insulated, it’s simply the most well-known testing company.

And just because pliers are “Rubber or plastic-coated” does not mean they are safe to use on potentially live electrical systems, always look for the double-triangle 1000V symbol to confirm they’re tested to IEC 60900:2018 standards.

Looking to buy? Maun has an extensive insulated pliers range here.

How Are Insulated Pliers Made?

Every manufacturing process will differ slightly, but Maun Insulated Pliers have the following properties:

- Encased in a durable, ergonomic industrial-grade polymer.

- Hand-stop guards to maintain safety separation between the handles and the head of the plier.

- Type tested to ensure that the finished plier and processes adhere to the IEC 60900:2018 standard, with random sample batch testing in production.

- Re-certified for any changes to the product construction or design.

- 100% of tools are dielectrically tested to 10,000 Volts.

- Marked with the double-triangle 1000V symbol according to the IEC 60900:2018 standard.

Types of Insulated Pliers and How They Are Used in Practice

Below, we’ve split the application scenarios by tool type, based on how they’re actually used on-site, in service calls, or in workshops.

Each tool offers different mechanical advantages and excels in specific trade environments.

Insulated Compound-Lever Action Diagonal Cutting Pliers

Best For: High-frequency cutting jobs, fault diagnosis, cable termination, and anywhere clean cuts in tight spaces are essential.

Important Features:

- Compound-lever Action: This boosts your hand force by up to 22x, which reduces the strain on your hands when cutting hard wire or heavy-gauge cable.

- Precision-ground Diagonal Cutting Edges: these deliver clean cuts, vital for ferrule prep, crimps, or terminals.

- Induction-hardened Jaws to HRC 64: This makes the cutting edge durable, meaning it will last a long time. No edge roll or splaying, even on 2.5 mm hard wire.

- Return Spring: This enables faster repetitive cuts without fatiguing your hard. Very useful in production or cable prep environments.

- Certified to IEC 60900:2018 (1000V AC/1500V DC): Safe for live work in commercial distribution boards, solar installs, or battery systems.

- Insulated Polymer Handles with Hand-stops: This makes them great to work with, and gives extra protection should you slip during use.

Use Scenarios:

- Cable Containment Prep (Tray, Basket & Conduit): They let you make quick cuts of cable ends when fitting into glands or trunking without fatiguing your hand. You can cut cleanly through solid or multi-strand cores, without deformed insulation.

- Solar/Battery/PV Work (DC Systems): Certified up to 1500V DC, these pliers are compliant for use with battery arrays, solar isolators, or inverter terminations. The HRC 64 induction-hardened jaws cleanly sever high-durometer insulation.

- HVAC & Controls Wiring: They’re perfect for installing sensors, thermostats, or comms wiring in plant rooms. The 140mm version fits neatly in belt pouches and works in junction boxes without excess tool length getting in the way.

- Data & Signal Line Termination: They’re ideal for trimming stranded data cable (CAT5e, CAT6) without damaging inner conductors, because of their accuracy and high leverage cutting design. Perfect for clean terminations or ferrule crimping.

Models:

- 1000V Insulated Diagonal Cutting Plier For Hard Wire Comfort Grips 140 mm

- 1000V Insulated Diagonal Cutting Plier For Hard Wire Comfort Grips 160 mm

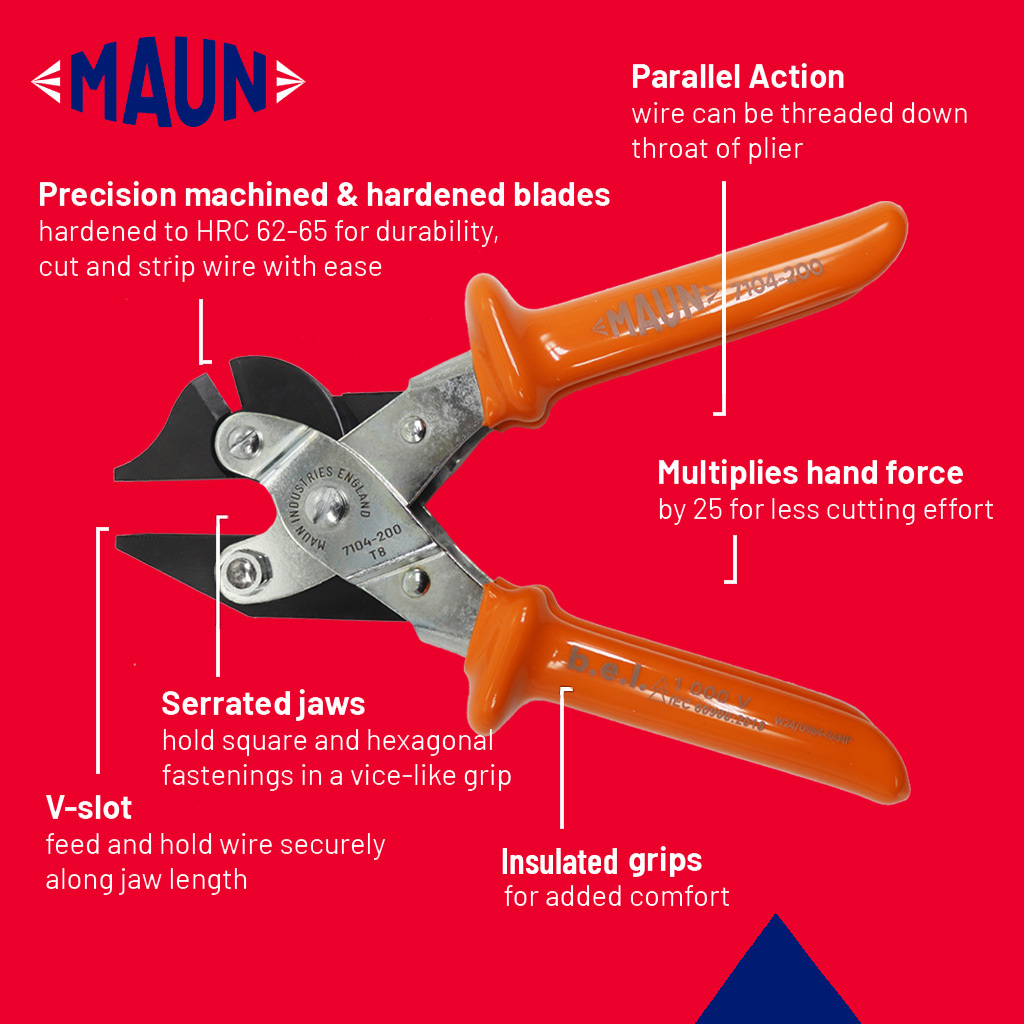

Insulated Side Cutter Parallel Pliers

Best For: Multi-function grip-and-cut jobs in electrical, maintenance, automotive, and industrial environments with live or potentially live circuits.

Important Features:

- Parallel-action Jaws: They grip evenly along their full length - perfect for holding terminals, square fixings, or awkwardly shaped fasteners without slipping.

- V-slot for Wire: This wire slot holds the conductor straight during cuts or stripping without crushing it, so you can prep multiple tails consistently and without damage.

- Integrated Side Cutter: These cutters handle everything from fine signal cable to up to 3.0 mm hard wire without the need to swap tools.

- Hand Force Multiplier: This means you have to put in less effort to cut through hard materials, leading to less fatigue. Particularly critical when working overhead or for long periods.

- Certified to IEC 60900:2018 (1000V AC/1500V DC): Safe for live work in commercial distribution boards, solar installs, or battery systems.

- Insulated Polymer Handles with Hand-stops: This makes them great to work with, and gives extra protection should you slip during use.

- Case-hardened Steel Jaws (HRC 57-65) - built to last under tough site use and repeated intricate wire cutting.

Use Scenarios:

- Control Panel Assembly (Live): Grip and trim stranded 1.5-6.0 mm² conductors in tight cabinets. The V-slot holds the wire precisely while the 25x force multiplication tackles up to 3.0 mm hard wire without hand strain.

- Maintenance Callouts (Reactive Jobs): Ideal when working quickly on 3-phase boards, lighting control gear, or faulty socket circuits. Parallel jaws give you a vice-like grip on worn or rounded fixings, and the hardened blades eliminate the need to swap tools to trim cable ends - particularly helpful if you’re up a ladder.

- Electric Vehicle Systems & Battery Banks: Use for gripping and cutting battery connector wire, braided copper straps, or insulated busbar tails, particularly in tight access zones where standard jaw designs slip or can’t maintain alignment.

- On-site Repair of Rigid Conduit/Armoured Cable Ends: If manipulating or removing damaged conductors from terminals, the parallel grip applies force along the full jaw, which helps you twist and straighten stiff or kinked cores before reconnection more easily than traditional pliers.

Models:

- 1000V Insulated Side Cutter Parallel Plier For Hard Wire Comfort Grips 160 mm

- 1000V Insulated Side Cutter Parallel Plier For Hard Wire Comfort Grips 200 mm

Safety Considerations

Here are some safety considerations before you use your tool:

- Visual Inspection Before Use: Check for nicks/cracks in the outer insulation.

- Keep Away from Sharp Objects: Prevent damage from knives, etc.

- Non-Insulated Parts Warning: Avoid touching any uninsulated sections of the tool.

- Cleaning & Maintenance: Regular cleaning extends the tool lifespan and maintains performance.

Insulated vs Non-Insulated Pliers

Insulated pliers are designed to protect you when working on or near live electrical systems (tested up to 1,000V AC/1,500V DC), whereas non-insulated pliers may have rubber or plastic grips but offer no electrical protection unless officially certified.

How To Tell If Pliers Are Insulated

The best way to check if pliers are insulated is to look for the double-triangle 1000V symbol (not just a voltage number) and a standard reference, such as IEC 60900:2018.

Are All Pliers Insulated?

No, unless stated, most pliers are not insulated, even if they have plastic or soft grips. If you want non-insulated pliers, we have a great range here.

Why Are Insulated Tools More Expensive?

Insulated tools are more expensive because they are individually checked to pass the high-voltage dielectric test and have strict manufacturing and traceability standards.

What is the Symbol for Insulated Tools?

The symbol for insulated tools is a double overlapping triangle with 1000V text next to it.

What Are Insulated Tools Red, Orange, and Yellow?

Insulated tools have bright handle colours (like red, orange and yellow) to help you quickly spot them.

Final Summary

That’s our summary of what you need to know about insulated pliers.

If you have any feedback or improvements you’d recommend for this post, we’d love to hear from you.

This post was brought to you by Maun, experts in tools since 1944.

Scroll back up to re-read any key points, browse our related pages below, or contact us with any questions: