How To Remove Shear Bolts

18th Nov 2024

Shear bolts are used to secure equipment or act as mechanical safety fuses.

But you can still remove them without the right tools and techniques.

Below, we’ll explain how they are used, and how to remove them, whether they’re a security bolt or built into a mechanical system.

1. Security Shear Bolts

In this context, the bolts are deliberately designed to frustrate attempts at tampering, making them difficult to extract without specialised tools.

This is important for security and safety, applicable to prisons, aerospace, and more.

The bolts are designed to create a smooth, rounded edge that’s very difficult to grip, and with the installation of a security washer, it makes it very difficult to access the edges of the bolt for any modification to gain grip.

Common use cases:

- Vehicle Steering Locks and Immobilisers: Precision is important, as a slip could cause costly damage.

- Industrial Security Panels: These fasteners are often buried in hard-to-reach areas of industrial machinery.

2. Shear Bolts in Mechanical Systems

Here the bolts are used within mechanical systems to act as sacrificial components or to prevent overtightening, breaking under stress to protect more vital parts.

These bolts shear cleanly under a set amount of load, leaving only a recessed or flush surface.

As the fitting of a shear bolt leaves a smooth domed surface, they also often used in areas of movement significantly reducing the risk of snagging when compared with other regular fixings.

Common use cases:

- Agricultural Machinery (Baler Flywheels, Combines): These fasteners prevent expensive damage to critical parts by absorbing shock or overload.

- Industrial Conveyor Systems: Used in conveyors to prevent motor or drive damage during jams.

- Lawnmowers and Snow blowers: Used to protect mechanical parts when the machinery becomes jammed or overloaded.

How To Remove Shear Bolts

Here are various techniques you can use to remove shear bolts:

Dremel Tool or Saw

One of the simplest brute-force ways to open a shear bolt is to use a Dremel tool or a small saw to cut a slot into the top of it.

This can then be used with a flathead screwdriver (or flathead attachment in an Impact Driver) to undo the bolt.

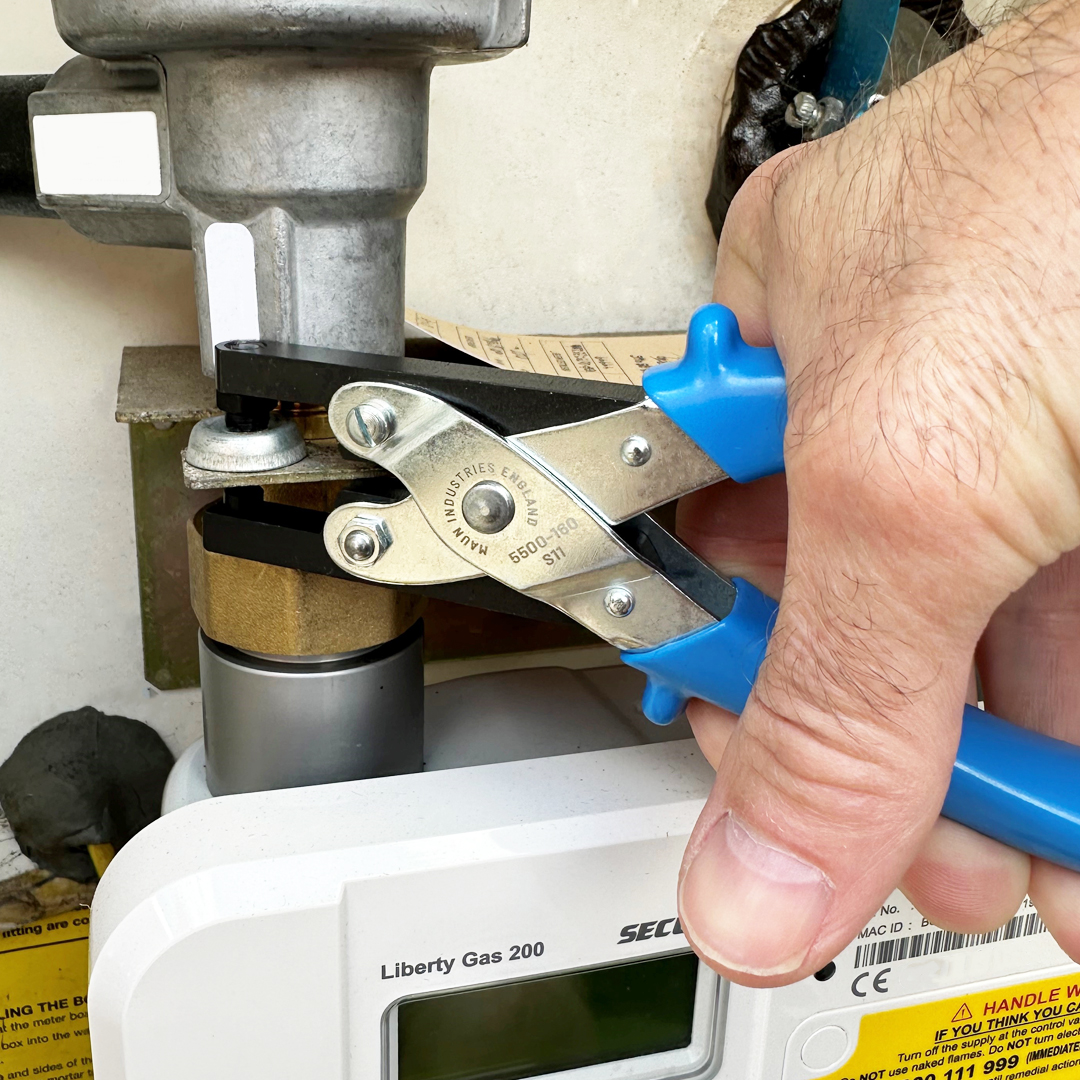

Shear Bolt Removal Tool

Maun has developed a specialist tool to quickly remove shear bolts, where access is available to both sides of the bolt.

It uses parallel jaws to align the removal dies onto the shear bolt evenly, providing minimal slipping.

This also greatly reduces the chance of easy breakages.

Delicate Method To Minimise Surrounding Damage

If you’re worried about tools damaging the surrounding area of the shear bolt, consider the following methods:

- Automatic Centre Punch + Pencil Rubber: point the tip of the punch at an angle on the outer edge of the bolt head facing anticlockwise, then strike with a hammer to break the seal. You can then use a rubber pencil end or pliers to unscrew the bolt once it’s loose.

- Drill Bit + Hex Key: use a small drill bit to create a hole in the centre of the bolt (to guarantee the centre, you can make a small indentation with a centre punch first).Then, gently hammer in a hex key that’s slightly larger than the hole you have drilled, and turn to unscrew the bolt.

- Punch and Plier: Split and remove the security washer using the punch. Using a pair of pliers with strong serrated jaws, grip the rim of the head to unscrew the bolt. We recommend a pair of parallel pliers as the parallel action of the jaws produces a vice-like grip that reduces the likelihood of slipping on the rim surface.

Shear Bolt Removal in Tight Spaces (Such as Car Engine Bays)

If you have limited room, such as within a car engine bay, you can try these techniques:

- Mig Welding – the idea is to stack weld blobs on top of each other until you have enough material to grip with a pair of pliers. Use these parallel pliers for a more consistent grip.

- Small, Sharp Centre Punch + Small Mallet – with limited space, you’ll want to use short, precise taps instead of large swings. If you're worried about damaging other components, you can wrap padding to the other side of your mallet.

Corroded Bolts

If the machinery has been used outside, or has come into contact with a lot of moisture, then the bolt may be corroded.

In which case, you can make it easier to open with the following methods:

- Freeze/Heat – to create a gap in the rusted bolt, we can change the temperature of the metal, which causes it to expand or contract.

- Penetrating Oils – these oils seep into the threads and help to dissolve the rust and free up the bolt for easy removal.

Final Summary

These methods should allow you to remove a shear bolt, whatever the scenario.

If you have any feedback or improvements you’d recommend for this post, we’d love to hear from you.

This post was brought to you by Maun, experts in tools since 1944.

Scroll back up to re-read any key points, browse our related pages below, or contact us with any questions: