Best Tools for Joiners

19th Feb 2026

Having the right tools makes joinery a joy to do.

Whether crafting custom furniture or installing high-end fittings, each tool should allow you to work quickly and accurately, so every job is executed to your standards.

Here are our top picks, broken down by categories:

Hand Tools

Hand tools bring control and finesse to joinery work, allowing you to refine each piece.

While power tools bring speed, hand tools enable the subtlety required for detail work.

- Chisels in Various Sizes and Profiles: A versatile set of chisels with different widths and edge profiles enables efficient work across different joinery types. Wider chisels excel at mortises, while narrower ones handle fine detail work, such as dovetail joints. Ergonomic, shock-absorbing handles help reduce hand strain during extended work, and a quality sharpening stone keeps chisels razor-sharp, reducing effort and ensuring cleaner cuts. Pro-tip: Keep a set of your “best” chisels for when you need a really sharp edge, and others for more day-to-day tasks.

- Square with High Accuracy for Professional Alignment: For a joiner, the square is a trusted standard of measurement. A solid engineer’s square with a graduated blade ensures accurate internal and external angles, ideal for assembling cabinets or frames. Consistently using a square prevents misalignments and structural issues. You can also use a pocket square for quick checks while working on larger builds.

- Rasps and Files for a Fine-Tuned Finish: Rasps and files are useful for edges and intricate shapes. Rough rasps quickly shape and smooth wood, while fine files are ideal for detail work. When crafting a custom cabinet corner, rasps allow smooth curves and consistent depth. Using a half-round rasp helps blend rounded edges into straight sections. Keeping them sharp makes for faster, smoother work without leaving uneven grooves.

- End Cutting Pliers for Flush Finishes: End cutting pliers offer a clean way to remove nails, screws, or fasteners, particularly when working with reclaimed wood or finishing repairs. The tool allows flush cuts, protecting delicate surfaces from damage. For example, when removing nails from a panel, end cutting pliers allow close gripping at the base, minimizing dents around the wood. Rubberized grips on these pliers provide better control, particularly for dense wood or repetitive tasks. Look for a set with compound-lever action jaws to make it easier to work with, such as these from Maun.

Power Tools

Power tools play a vital role in a joiner’s workflow, providing productivity and control over tasks that could otherwise take far longer by hand.

Each tool in your kit should be dependable, versatile, and tough enough to handle varying materials and demands.

- Cordless Drill/Driver with Torque Settings: A well-equipped cordless drill goes beyond basic drilling functions; adjustable torque settings help prevent overdriving or stripping screws. Low torque works well with softer woods, allowing screws to settle without splintering, while higher torque is ideal for harder materials. An adjustable chuck accommodates various bits for tasks from making pilot holes to hinge installation. Choosing a model with fast-charging lithium-ion batteries—and keeping a spare on hand—ensures uninterrupted power during peak hours.

- Jigsaw with Multi-Function Blades: A quality jigsaw, especially one with variable speed control, adapts to cutting a range of materials from MDF to hardwood. Multi-functional blades for fine, rough, or curved cuts help you achieve clean finishes. Look for a tilting shoe offering angled cuts up to 45 degrees, and use tungsten carbide blades for tackling dense materials without rapid dulling. A trick among seasoned joiners is to apply masking tape along the cutting line to reduce splintering on delicate veneers.

- Electric Planer with Adjustable Depth: Electric planers are used for precise thickness adjustments on wood edges and surfaces. A planer with depth control down to 0.1 mm allows gradual shaving on delicate work. Multiple depth settings allow for both rough and fine planing. On large projects like door fittings, adjustable depth settings make it easy to remove material gradually and evenly, aligning edges without chipping. Planers with dust bags or extraction ports help keep your workspace clear, preventing dust buildup in grooves that might interfere with finishing.

- Circular Saw with Depth Settings: For quick cuts across a range of materials, a circular saw is invaluable for a joiner. The depth settings allow you to avoid cutting too deep, for example if you’re cutting through floorboards, to avoid hitting any pipes or cables below the depth of the boards, or accidentally cutting into a joist.

Measuring and Marking Tools

Precision in joinery begins with accurate measurement.

Reliable measuring and marking tools ensure every cut, joint, and alignment matches your designs.

- Reliable Tape Measure and Rigid Steel Ruler: A tape measure with a nylon-coated blade resists bends and kinks that throw off measurements on long spans, while a rigid steel ruler ensures perfect alignment for short distances (like this one from Maun). Using both tools when setting up a row of cabinets, for example, ensures seamless alignment. A tape measure with both metric and imperial units provides flexibility across different project specifications.

- Combination Square for Versatile Measuring: A combination square functions as a depth gauge and marking guide, useful for setting consistent depths in mortises or marking diagonals on larger builds. Its adjustable head helps mark repetitive measurements precisely, whether cutting multiple timbers or setting up joints on a bench.

- Steel Straight Edge for Consistent Alignment: A steel straight edge ensures accuracy over longer spans, useful for marking plywood cuts or drawing straight lines on laminates (see the Maun precision-engineered straight edges here). It’s a favourite when marking longer planks or setting up cross-cuts, eliminating waviness in alignment that can compromise both appearance and stability.

- Digital Calliper for Precision Work: Digital callipers provide millimetre-precision, essential for fine joinery work, especially when combining materials like wood and metal. For example, using callipers on a project with metal trims for wood panelling allows exact widths on each cut, so the trim fits perfectly flush.

Clamps

Clamps provide important stability during assembly. The right clamp type and size turn complex setups into manageable tasks, allowing you to focus on accuracy without worrying about shifting pieces.

- Quick-Release Clamps for Speed and Convenience: Quick-release clamps enable easy repositioning and adjustment on the go. They’re lightweight but strong, ideal for solo joiners on multi-part assemblies. Rubberized grips prevent marks on softwoods, reducing slippage and providing even pressure when gluing up larger surfaces like tabletops.

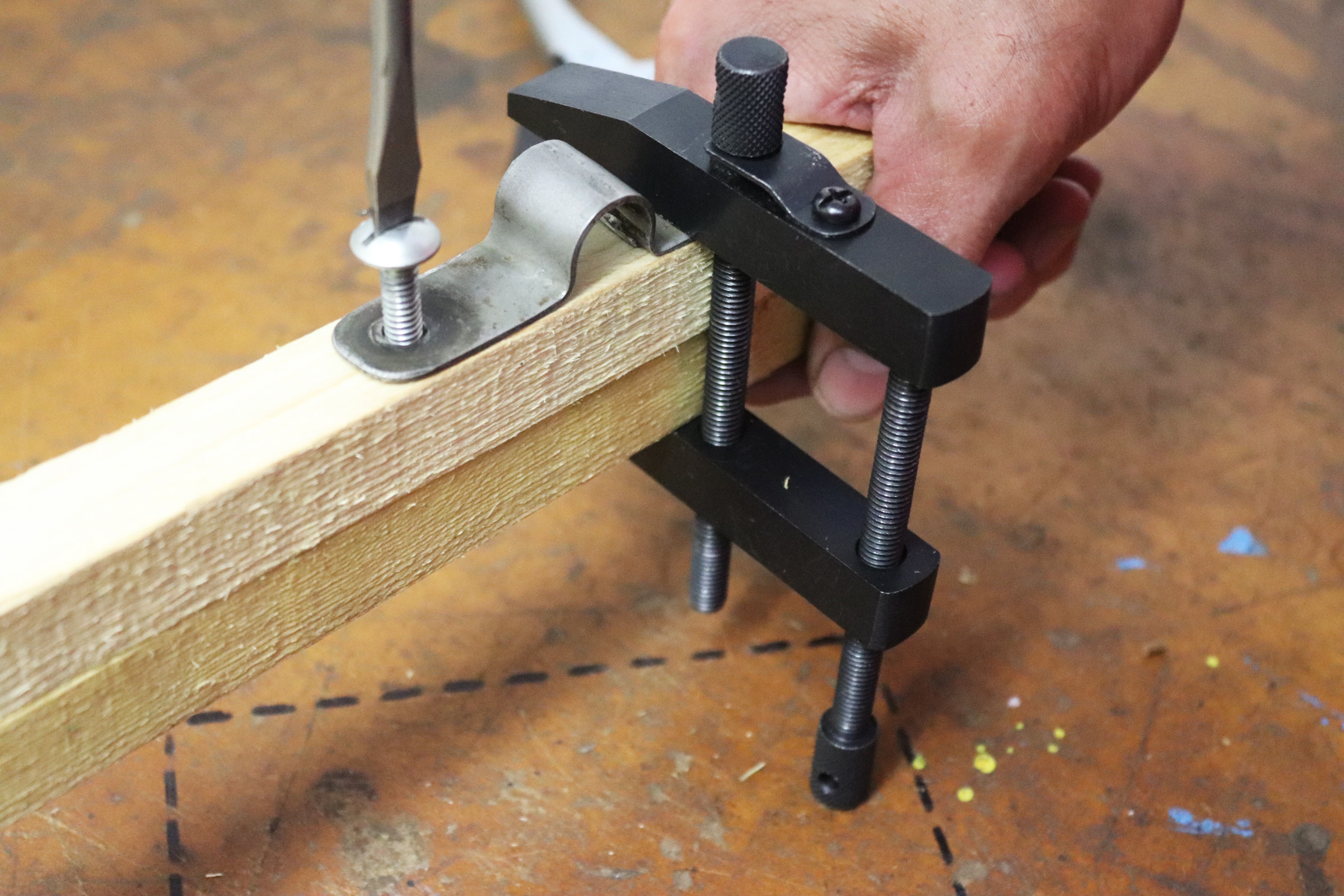

- Small Parallel Jaw Clamps for Strength in Tight Spaces: If you’re working with smaller pieces and need accurate clamps that don’t get in the way, consider these Toolmakers Clamps. They use parallel jaws, which helps them grip well even when the contact point is small, and they aren’t overly bulky, making them great for making smaller cuts or holes.

- Heavy-Duty G-Clamps for Stability on Larger Projects: G-clamps are crucial for large or heavy components requiring maximum grip strength. Their stability makes them reliable for securing beams or large boards during assembly, helping ensure frames or shelving units stay aligned. One joiner found G-clamps invaluable when securing beams on a shelving installation, allowing him to achieve the needed stability in an otherwise challenging setup.

- Corner Clamps for Precise Angles: Perfect for 90-degree joints, corner clamps ensure clean, square alignment on frames, cabinets, or other items with right angles. They’re especially useful when gluing, holding pieces steady as adhesive sets. Corner clamps make multi-piece alignment easier, especially for drawer units or mitre joints where even minor misalignments affect the overall fit.

Sanding and Finishing Tools

Sanding and finishing complete the work, creating smooth surfaces and enhancing wood’s natural appeal.

- Random Orbital Sander for Consistent Smoothing: An orbital sander is ideal for preparing large surfaces evenly without leaving grooves. Models with variable speed and dust extraction keep the workspace cleaner and ensure visibility on the wood surface. Use progressively finer grits, starting with 80 or 120 for rough areas and finishing with 240 or 320 for a polished effect. This process is particularly beneficial on visible surfaces, ensuring a consistent, professional finish.

- Hand Sander for Detailing: A hand sander offers control over edges and tight spaces, ideal for curved or intricate mouldings. Use a foam sanding block to follow the wood’s contours, preventing flat spots while maintaining the natural shape.

- Finishing Oils and Waxes for Protection and Appeal: Finishing products not only protect wood but also highlight its natural grain. Hard wax oils provide a durable finish, while tung or Danish oil brings out the grain’s depth and character.

Final Summary

Now you can upgrade your toolkit for better joinery,

If you have any feedback or improvements you’d recommend for this post, we’d love to hear from you.

This post was brought to you by Maun, experts in tools since 1944.

Scroll back up to re-read any key points, browse our related pages below, or contact us with any questions: